2025/12/08

2025/11/05

2025/11/05

2024/06/26

NOVOSENSE's NSD830x-Q1 is a series of multi-channel half-bridge automotive-grade driver chips. It includes NSD8308 (8-channel) and NSD8306 (6-channel), integrating multi-channel half-bridge driver and N-MOS power stage to support multiple load types.

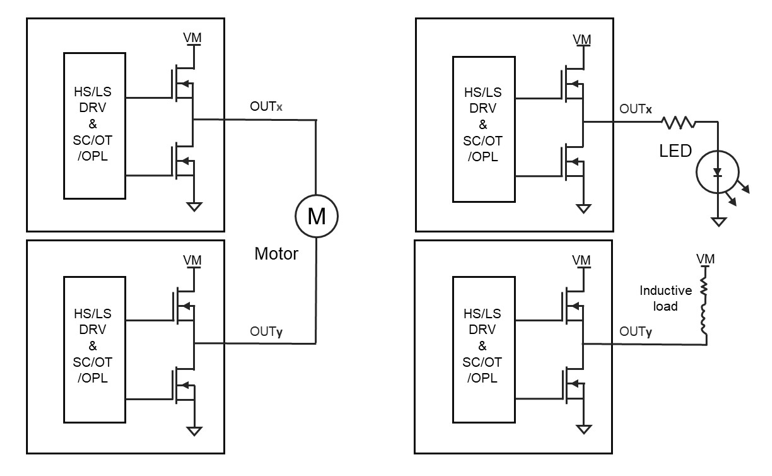

Figure 1: Motor/LED/Inductive load

As shown in Figure 1 above, this product can be configured via SPI to offer both full-bridge and half-bridge drive modes, supporting brushed DC motors, stepper motors, relays and LEDs. It is ideal solution for HVAC and climate control, mirror control and ZCU in automotive systems.

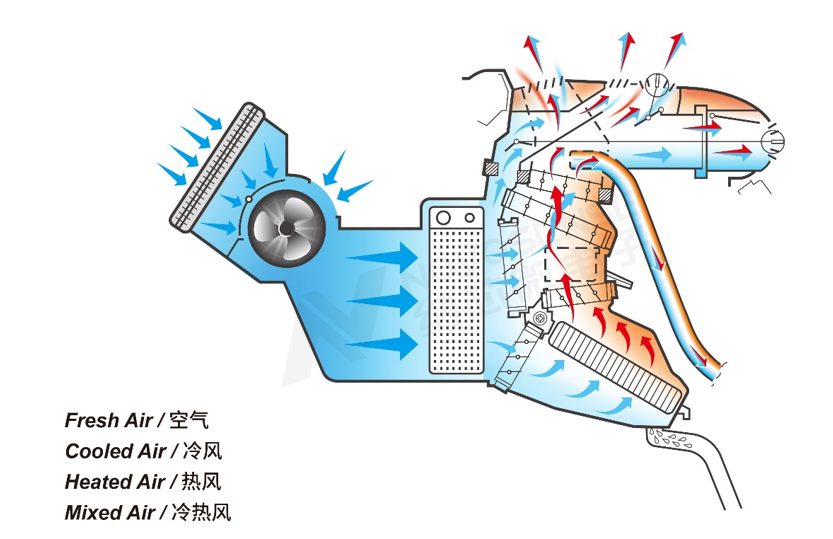

Figure 2: Automotive thermal management system

Features of NSD830x-Q1

- Wide operating voltage range: 4.5V-36V (Absolute max rating 40V)

- Rdson(HS + LS): 1.7Ω

- Peak current: 1A

- PWM generator supports configurable frequency and duty cycle

- Open load diagnostics

- Undervoltage protection and overvoltage protection

- Working temperature: Tj=-40°C~150°C

- AEC-Q100 qualified

- Package: HTSSOP-24, HTSOP-24

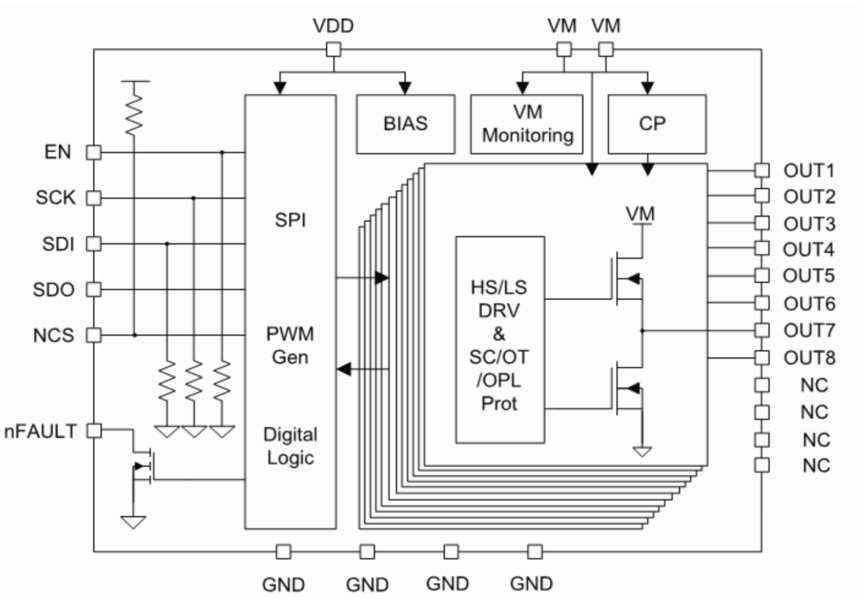

Figure 3: Functional block diagram of NSD8306

NSD830x-Q1 not only offers an SPI interface and multi-channel drive mode but also features various additional functions to flexibly support a wide range of loads:

I)PWM Generator

NSD8308/NSD8306-Q1 is equipped with PWM generator capable of adjusting the PWM frequency and duty cycle through the configuration register. This feature helps control the speed of the DC brushed motors and dim LEDs, reducing the workload of the main control chip and saving I/O resources.

The PWM generator supports frequencies from 80-2KHz and an 8-bit resolution duty cycle, which means that this product series can support a duty cycle, covering a range of 0-100% and allowing for 0-255 subdivision changes

Even without PWM control commands from the MCU, the motor load could achieve soft start and speed regulation, and simple PWM dimming can be realized in LED applications. As shown in Figure 4, when the register sets the output to 100Hz with a duty cycle of 25%, 50%, 75%, the corresponding channel accurately matches the configured frequency and duty cycle.

Figure 4-1: PWM Generator at 100Hz 50% Duty Cycle

Figure 4-2: PWM Generator at 100Hz 25%/50%/75% Duty Cycle

2) Output Current Limiting

During the design of motors and other load systems, small capacitors are often connected in parallel at the output Pin to reduce EMI or enhance immunity. The current limiting function ensures longer peak current provision for capacitive loads compared to traditional OCP function.

NSD8308/NSD8306-Q1 provides current limiting protection for both the high-side and low-side of the half-bridge. If a short circuit or overcurrent occurs and the load current exceeds the defined threshold, the output enters current limiting mode. This function reduces the likelihood of "false alarms" from transient currents caused by capacitive loads or parasitic parameters, thus maintaining normal equipment operation.

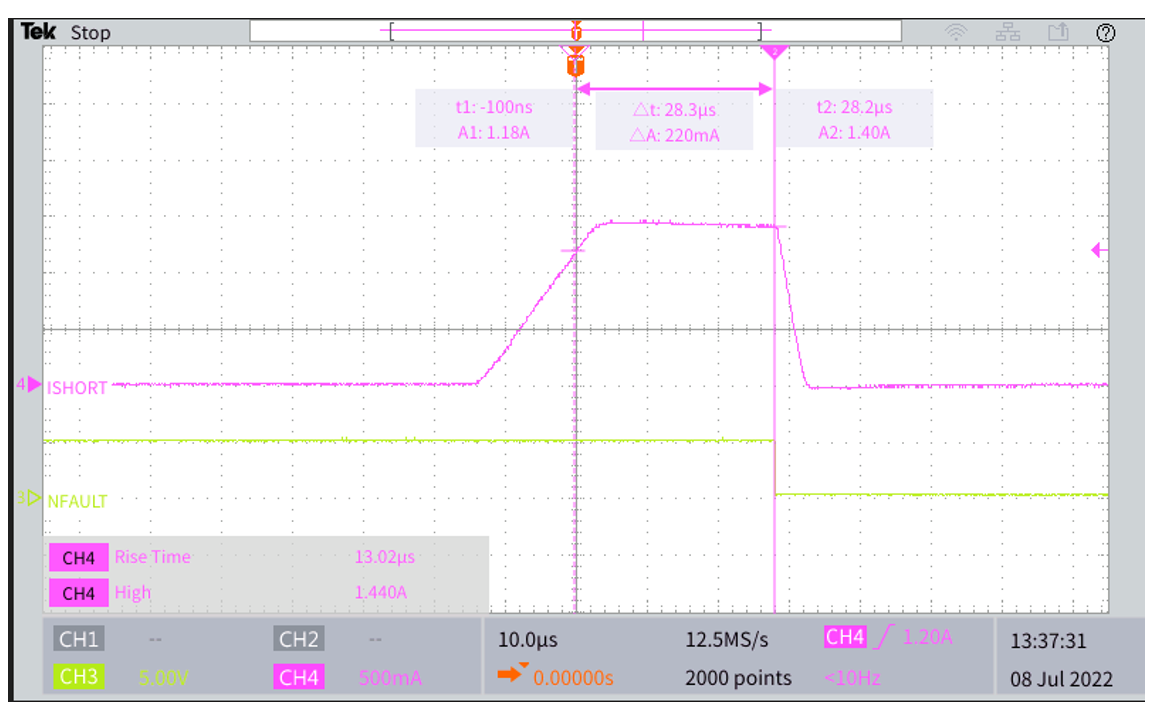

Figure 5: waveform of output short-circuit current limiting

3) Load Diagnostics

As intelligent EV increasingly require monitoring and diagnosing of the load working status, NSD8308/NSD8306-Q1 provides intelligent load diagnosis. This feature determines the load connection status and, in the event of a short or open circuit, allows the external controller to retrieve status information for each independent channel via the chip's internal registers.

The diagnostic function covers different loads working status and supports multiple load connection methods, including half-bridge, full-bridge, high-side and low-side. In offline mode (driver output off), it facilitates open-circuit, battery short circuit, and ground short circuit diagnosis. In online mode (driver output on), it allows for open-circuit diagnosis and current limiting protection. Status and alarm for the corresponding output channel can be reported to the main controller through SPI.