NSP1832 series MEMS differential pressure sensor wafer is mainly made via the piezoresistive effect of silicon with NOVOSENSE independent R&D MEMS micro machining process design. The sensor wafer manufacturing platform is qualified by IATF16949, and the front/back side of every wafer pass AOI tested which compiles with AEC-Q103 standards. NOVOSENSE also launched unique precious metal differential pressure MEMS series products, which mainly adopts precious metal double-pad structure design and stability enhanced shielding layer technology, and specially used in automotive exhaust system and other harsh environment.

Product Features

• Operating temperature range: -40℃~150℃

• Pressure range: 0kPa~±5kPa/±35kPa/±100kPa

• The accuracy and stability in the life cycle are better than 1%F.S.

• Automotive-qualified IATF16949-certified process platform

• Comply with RoHS & REACH and halogen-free requirements

• Compiles with AEC-Q103 standard

• Single chip size: 1.65mmx1.65mmx0.4mm

Application

• Automotive: FTPS fuel steam pressure detection, GPF/DPF exhaust differential pressure detection, VBS vacuum boosting system sensor, EGR system differential pressure detection, Crankcase ventilation pressure sensor

• Industrial: fire residual pressure monitoring, HVAC/VAV, pressure transmitter, pressure switch, negative pressure vacuum detection, gas flow monitoring

• Medical: ventilator, sphygmomanometer, oxygen generator, anesthesia apparatus, biosafety cabinet

• Home appliances: washing machine, dishwasher, coffee machine, vacuum cleaner, water purifier, vacuum juicer, etc.

• Consumption: air mattress, massage chair, air pump etc.

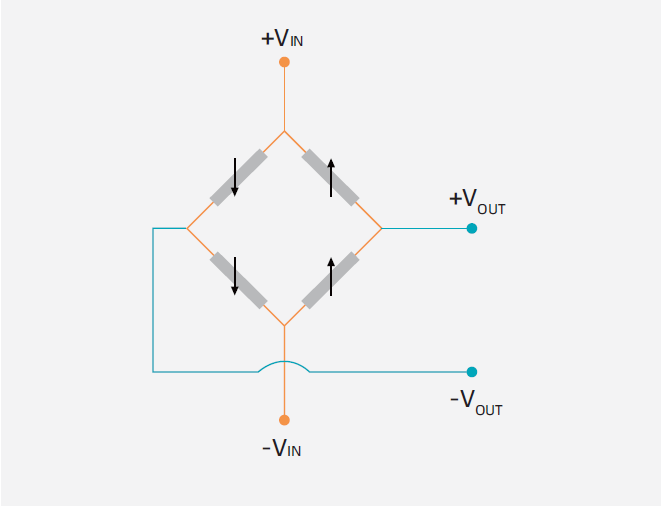

Functional Block Diagram

For more product information, please contact us.