2024/03/14

With the improvement in people's living standards and the growing demand for a more comfortable living environment, China's central air conditioning market has maintained relatively stable growth. Temperature and humidity, pressure, and current sensors with high-precision detection capability are critical to the various functions of central air conditioning. As a manufacturer of high-performance, high-reliability analog and mixed-signal chips, NOVOSENSE offers a wide range of sensor and analog IC solutions for central air conditioning applications.

Development trends and new requirements for central air conditioning

According to statistics, in the first half of 2023, in China's central air conditioning sales, multi-connected systems accounted for approximately 51%, continuing to rank first in the market. The reason why multi-connected systems are favored by the market mainly lies in their low installation cost, flexible applications, and high energy efficiency. For this reason, some well-decorated homes have also begun to standardize on this type of air conditioning.

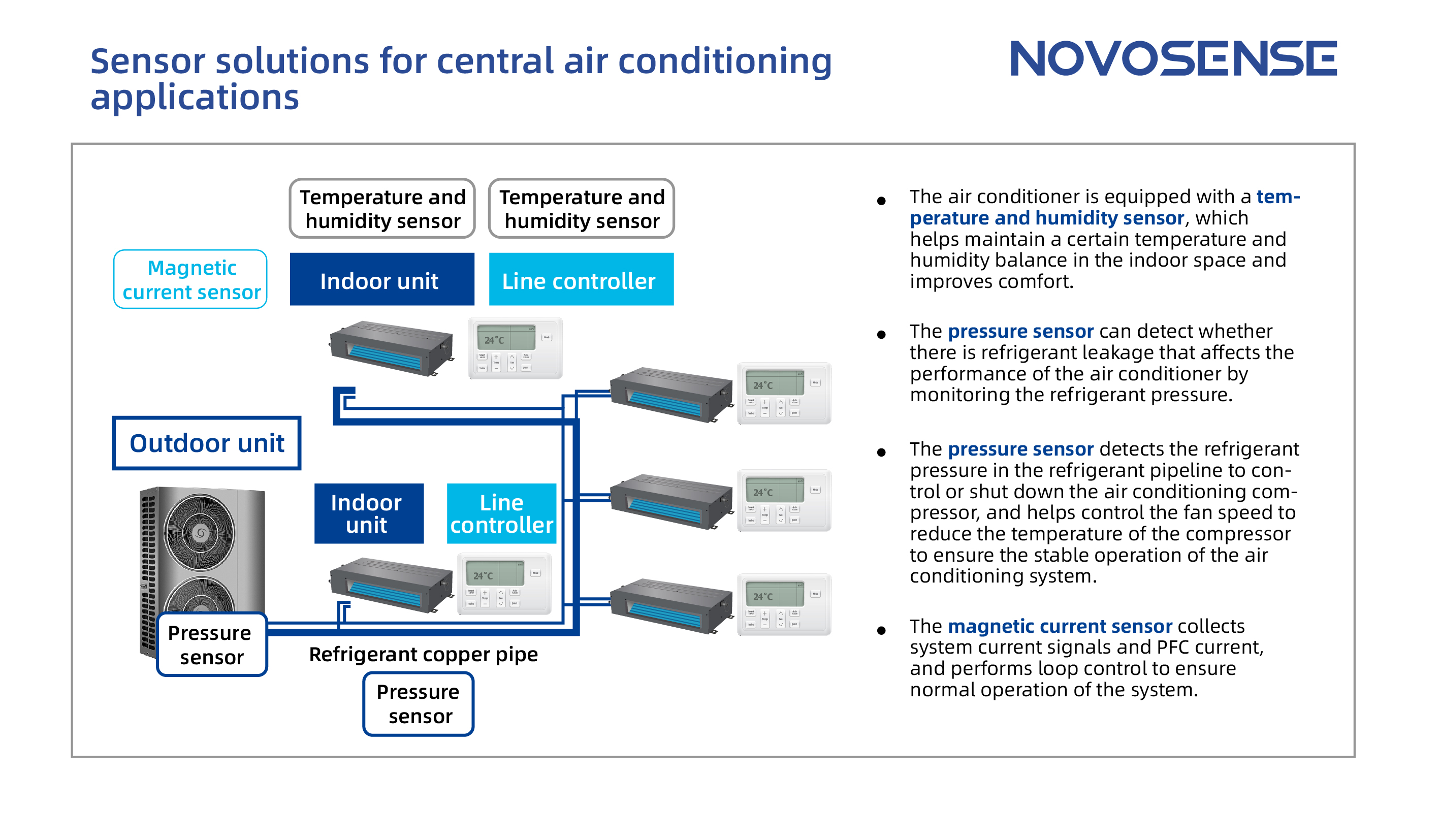

Commercial central air conditioners adopt a one-to-many architecture, in which an outdoor unit drives multiple indoor units. Each indoor unit has a corresponding line controller, which can automatically adjust the air outlet, airflow, and cooling and heating power through the feedback of temperature and humidity to maintain a comfortable indoor temperature.

The development trend of multi-connection technology is mainly reflected in two directions. One is energy saving and noise reduction: outdoor units and even indoor units have frequency conversion capabilities, which can reduce noise by increasing the frequency while achieving low standby power consumption. The other is better comfort and improved environmental performance: meeting specific requirements for airflow, temperature and humidity control while reducing the damage of refrigerant leakage to the natural environment to ensure effective air conditioning.

· NOVOSENSE's sensor products can exactly meet the above trend requirements. These products include temperature and humidity sensors and pressure sensors that meet comfort and environmental performance requirements, magnetic current sensors that ensure normal operation of outdoor units, and various analog IC products.

NOVOSENSE offers comprehensive sensor solutions for central air conditioning applications

The temperature and humidity sensor is used to detect the ambient temperature and humidity to control the airflow from the air outlet and balance the ambient humidity for improved comfort.

NSHT30 is a temperature and humidity sensor with very small size and very high accuracy. It adopts a 2.5mm×2.5mm small package (LGA and DFN options). The MCU reads the temperature and humidity data through the I²C interface of the sensor. Temperature and humidity measurements are from -40°C to 125°C and from 0 to 100%, which can basically cover all temperature and humidity ranges.

The advantage of NSHT30 is, first of all, the response time. The acquisition time of temperature and humidity is only 2s and 6s, respectively. Its accuracy is also higher than other similar products in the market. The chip calibration before leaving the factory can ensure high accuracy requirements. Under the condition of 0~50°C, the error of NSHT30 can be controlled at ±0.3°C (typical value); and under the condition of 50% relative humidity, the error can be controlled at ±3% to meet the accuracy requirements of air conditioning.

The pressure sensor is usually placed on the outdoor unit or refrigerant transmission pipe to detect refrigerant leakage and refrigerant pressure, ensuring effective air conditioning while achieving environmental performance.

NSPAS3 is an integrated absolute pressure sensor for refrigerant leakage pressure detection in air conditioners. Its operating temperature is from -40°C to 130°C, and its internally integrated temperature compensation circuit can achieve ±1% control accuracy in the range of 0~85°C and ±1.5% control accuracy in the range of -40°C to full temperature.

NSPAS3 is compatible with the pressure test range of 10kPa~400kPa and can detect refrigerant leakage pressure. The standby power consumption of this product is less than 3mA, and the response time is within 0.8ms. In addition, the chip package is coated with anti-corrosion jelly glue, which can prevent some corrosive gases from damaging the chip package.

NSC2860x is a capacitive pressure transmitter signal processing ASIC solution. It can detect the refrigerant pressure (3~5MPa) in the air conditioning compressor. The chip integrates various digital components such as PGA, ADC, MCU and various interfaces. It has a very high degree of integration and can convert the monitored pressure into a digital signal for processing by the MCU. NSC2860x also integrates a 4-20mA loop power supply, which enables longer distance transmission to meet the communication distance requirements between the pressure sensor and the MCU main control board in the refrigerant system.

The magnetic current sensor is generally placed in the outdoor unit and is mainly used to monitor the current of the outdoor unit, such as PFC current or phase current of the air conditioning compressor motor. It achieves tracking feedback by collecting system current signals to ensure normal operation of the system.

NSM2019 is an integrated Hall current sensor, mainly used to detect the motor current or PFC current of the air conditioner. The MCU reads the current value through the VOUT pin. It integrates the reference voltage and OCP (overcurrent protection) internally, eliminating the need for some peripheral devices such as comparators or op amplifiers. This product covers a range of 20A~200A, which can meet the power requirements of commercial air conditioners from several kilowatts to one hundred kilowatts.

NSM2019 has an accuracy of ±2% and can guarantee accuracy over the full temperature range. Its isolation withstand voltage is up to 5,000V, the creepage distance is up to 8.2mm, and it can withstand 20kA surge current. Its input bandwidth is as high as 320K, which can meet the bandwidth requirements of current detection. Due to the small internal resistance, the heat output of the chip is also small.

Other analog IC solutions for central air conditioning applications

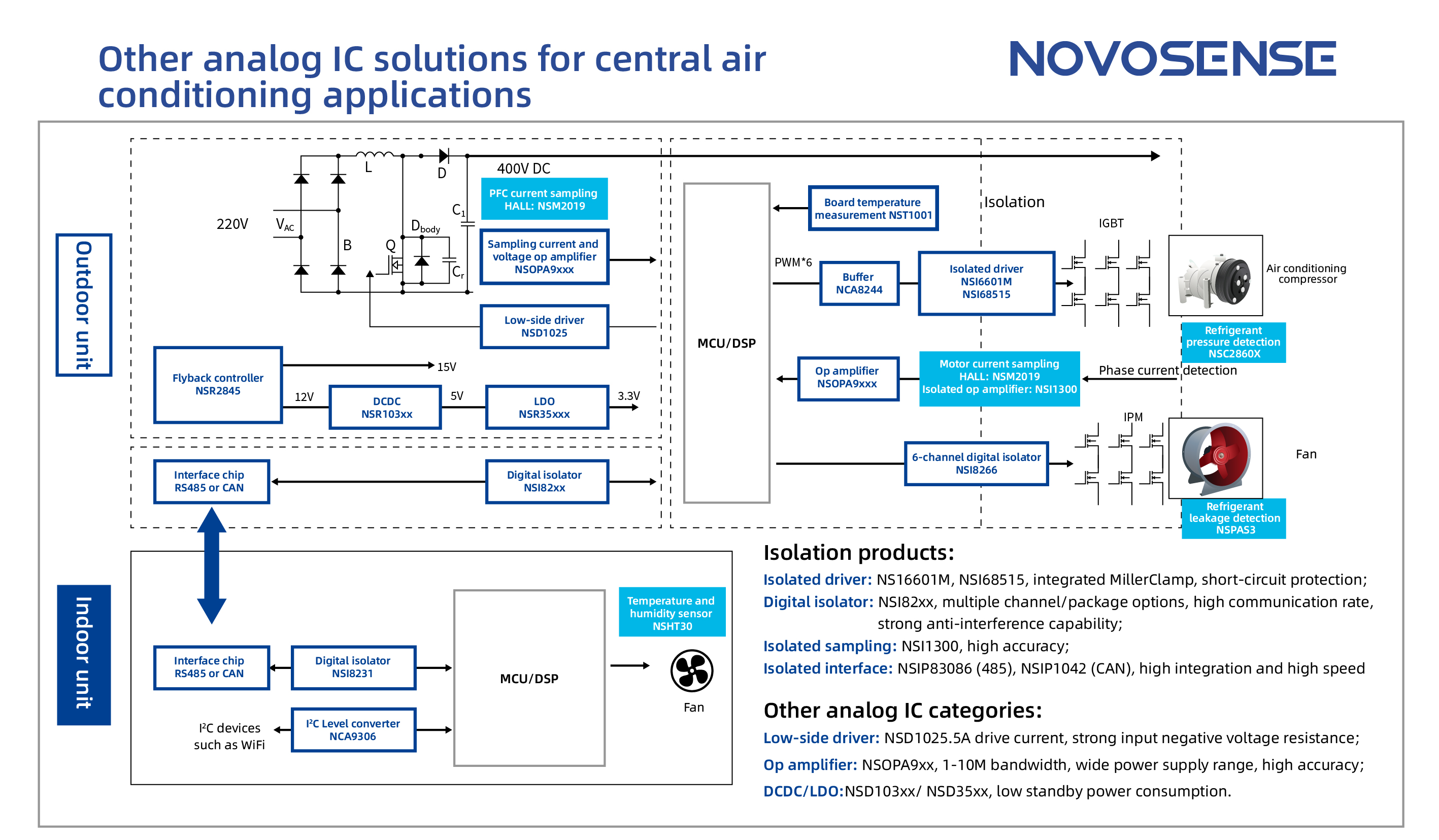

In addition to sensors, NOVOSENSE offers many analog IC product solutions. Analog ICs are mostly used in outdoor units. The topology of the outdoor unit determines that the 220V mains power needs to be rectified by PFC to approximately 400VDC, which then feeds the bus voltage of the two motors. The motor is directly driven by IGBT or IPM. The MCU that drives the IGBT is usually placed at the low voltage end, so it is necessary to use an isolated driver to rotate the motor. As a result, many isolated driver products are required. At the same time, the current and voltage must be monitored. The PLC also needs to collect the voltage and current, so op amplifier products are also used.

The outdoor unit and the indoor unit communicate through 485 or CAN bus. Since the two generally do not share a common ground, some isolated interfaces are also needed. NOVOSENSE provides digital isolator products that convert high voltage to low voltage to power MCUs. The power supply is usually converted from high voltage to low voltage by flyback power supply, then converted to 5V by DC-DC, and then converted to 3.3V by LDO to power other chips.