Digital isolators now enjoy increasingly greater popularity than optocouplers. Will you really choose a digital isolator? Since digital isolators provide basically same functions with optocouplers, these two device categories have many similar parameters, but also different ones. This article will talk about how to select a digital isolator using its datasheet.

Explore further after datasheet reading

When it comes to device selection, it’s advisable to turn to the datasheet. Speaking of datasheet, here may a slight digression. Previously, Chinese chip makers didn’t give due attention to datasheet, and it’s not easy to access the datasheet of a device. Now the datasheet of many products are easily available on the official website of the corresponding manufacturer. This reflects that Chinese chip makers dare to “battle” with global manufacturers in device parameters.

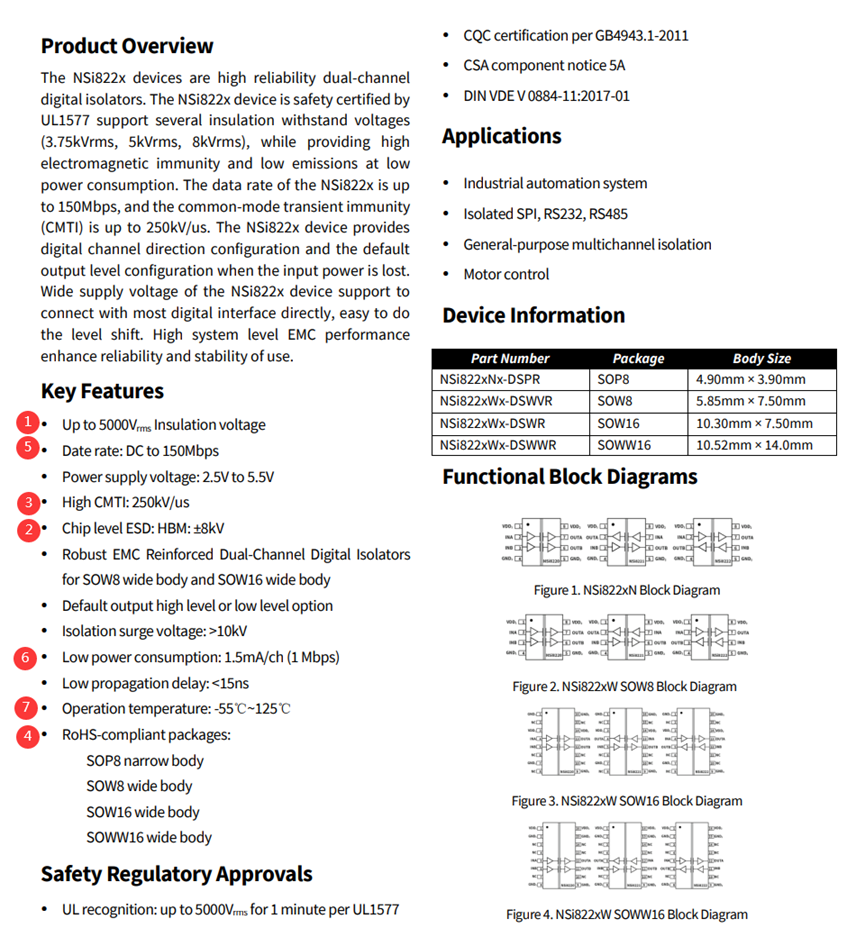

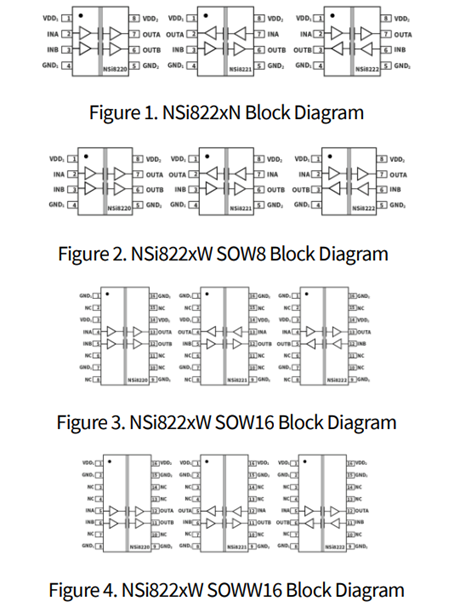

Datasheet can be seen as the instruction manual of a device. Generally, the instruction manual of a product is devised in a progressive way, from overview to detailed parameters and then to the do’s and don’ts. This is also true of a datasheet. However, datasheet has its specific format, which includes introduction, key parameters, safety approvals (isolators can affect safety, so safety approvals are mandatory), applications, basic device information (package and size), and block diagrams.

Accordingly, we should gradually determine the requirements and narrow the scope of selection. When we have a datasheet, the first step is to read the overview on Page 1, which is a brief summary of the product typically including parameters and introduction. It allows us to have a fast understanding of the performance indicators of the chip in a short time. Product selection and prototype verification are often the most time-consuming part of system design. Therefore, a detailed reading and understanding of the overview section is very helpful for our early-stage screening of devices.

Afterwards, we should have a clear picture of the application’s specific requirements and evolution trajectory. A datasheet typically lists suitable applications, such as automotive, photovoltaic, motor, and industrial automation, etc.

We have got a general picture of the product from the above-mentioned section of the datasheet. To select an ideal device for an application, more details are required. Here comes what we will talk about next – What parameters of digital isolator should be focused on?

Look into the whole story behind parameters

For a digital isolator, what parameters are important enough to warrant attention? To avoid talking on paper level, we asked Ye Jian, Product Line Director, NOVOSENSE, to share his insights. Having worked in the isolator field for years, Ye has fully witnessed how digital isolators replace optocouplers. Taking NSI82xx-Q1SWWR high-reliability multi-channel ultra-wide-body digital isolators for example, he explained the datasheet of digital isolators in detail.

Although a datasheet lists an array of parameters that may leave you at a loss, such as insulation voltage, CMTI, package, data rate, power consumption, and ESD, Ye identified the items that should be given great attention. Specifically, he listed the following seven key parameters (in no particular order) using NOVOSENSE products as an example.

First, insulation voltage. Isolator is a device that is required to comply with safety regulations, so the isolator selection must be made around safety. Insulation voltage is the most important influencing factor of safety. For example, NOVOSENSE offers a range of basic and enhanced isolators that feature different withstand voltage ranges, so as to meet different system requirements of customers.

Second, ESD. ESD protection is an important contributor to high reliability of isolator. For the vast majority of chips, ESD immunity is a must-have property, but the capability level requirement depends. Isolators are placed in high-voltage environment, usually the high-low voltage interface in the system, so ESD immunity is also extremely important. NOVOSENSE isolators provide HBM withstand voltage of up to 8kV, the highest chip-level HBM ESD.

Third, CMTI. It is another key parameter of isolator, which measures a chip’s capability to resist transient interference, that is, the device’s robustness in system applications. CMTI refers to the maximum tolerable rate of short time voltage rise or fall to the value that can destroy the output state of driver. The transient interference is caused by the high DV/DT on the switching node. If the CMTI capability is insufficient, output error or even short circuit may occur, affecting the system safety. The CMTI of isolators from NOVOSENSE is mainly ±200kV/μs, and can even reach ±250kV/μs in some models.

Fourth, package. Package here is more than body size, and is also related to such parameters as withstand voltage and safe creepage. Different chips will be provided depending on customer requirements or system requirements, but the ultimate objective must be meeting the safety requirements in a smaller and higher-integration package. For example, NOVOSENSE provides different package types including SOP, SOW and SOWW to answer different safety requirements, which will be elaborated later.

Fifth, data rate and propagation delay. Data rate is an indicator of whether a digital isolator is high-performance, which can be up to hundreds of Mbps or even Gbps level. Different communication standards and interfaces have different requirements for data rate, which need to be carefully checked. However, Ye also underlined that data rate, be it 1Mbps or 150Mbps, has small impact on the device cost. That’s why NOVOSENSE does not provide more product categories by data rate. Instead, basically all digital isolators from NOVOSENSE provide a data rate of 150Mbps, which can meet the requirements of the majority of applications. In addition to data rate, there will also be detailed parameters related to timing in the datasheet, which should also be taken into consideration in the system design.

Sixth, power consumption. According to Ye, the power consumption of digital isolators has been greatly reduced, relative to optocouplers. Therefore, the power consumption requirement is relatively small, but the datasheet will still describe the power consumption level under various conditions.

Seventh, operating temperature. Operating temperature is strongly linked to applications. For example, there are four grades of automotive digital isolators, from Grade 0 to Grade 3, which pose different operating temperature requirements. A Grade 0 device is required to cover the temperature range of -40°C-150°C. Industrial digital isolators have different temperature requirements depending on applications, and the maximum requirement is typically -40°C-150°C. These are described in detail in the datasheet.

How can package make a difference

As stressed by Ye, package can make a very big difference for isolators. The main reason is that the package size can directly affect the withstand voltage capability of a device. Therefore, particular attention needs to be paid to package. All desire compact devices, but the realization of higher isolation voltage requires a wider-body package. NOVOSENSE has introduced regular package, wide-body package, and ultra-wide-body package. The advantages of ultra-wide-body package are mainly reflected in two parameters – creepage of 15mm, and isolated withstand voltage of 8 kVRMS. Enhanced isolators can provide an insulation level comparable to two basic isolators connected in series. This makes enhanced isolator a perfect choice for some special applications, for example, photovoltaic inverter.

Different package types from NOVOSENSE and their detailed parameters listed in datasheet

In short, a larger package will allow higher isolation voltage specifications. If you can choose a smaller package to meet the regulatory requirements for the system, the smaller package undoubtedly helps reduce the footprint on board and costs. In addition, you need to consider how many isolation channels the communication interface requires, because the higher the number of channels is, the more important the package type will be.

Clearance and creepage are two different parameters. Clearance is the shortest spatial distance measured between two conductive parts or between a conductive part and the device interface. Creepage refers to the shortest distance between two conductive parts or between a conductive part and the device interface measured along the insulating surface.

Clearance and creepage can be affected by environmental pollution level, altitude, and CTI. Particularly in solar and wind power and other continuously operating applications in harsh field conditions, altitude and pollution have a very high impact on clearance and creepage. How can the clearance and creepage requirements be met while reducing the overall size? The CTI of NOVOSENSE products reaches 600V, which can minimize the creepage requirements of the system, thus reducing the system size.

Safety standards are crucial

Meeting the parameter specifications alone does not mean the end of isolator selection, and due attention needs to be paid to safety approvals. Isolator is a safety related device, so safety approvals are often shown in the most visible position. For example, the first page of a NOVOSENSE datasheet gives the safety approvals of the device, including UL1577, CQC, CSA and VDE. The reason why certification standards matter greatly is that manufacturers can easily obtain the system safety approvals, provided that they select products that have won safety certification, so that their systems can be used and sold worldwide with great confidence.

UL1577 standard is a key component level certification requirement for digital isolators, and is applicable to optocouplers, magnetic isolators and capacitive isolators. To obtain the UL1577 approval, a device must withstand the isolation voltage VISO (specified by the manufacturer, usually 2.5kVRMS or 5kVRMS) for 1 minute. The standard also provides that isolators are required to pass 100% production tests using 120% isolation voltage for 1 second.

In addition, digital isolators also need to refer to regional safety certification standards, such as CQC, CSA, and VDE. Behind the safety approvals are strict test procedures. A device is required to pass aging test, high withstand voltage test, sampling test, extended temperature test, life test and others. It’s especially noted that a complete cycle of life test lasts more than half a year.

Passing certification tests of agencies does not mean a once-and-for-all thing. When a device is put into mass production, each product needs to be tested. For example, each isolator from NOVOSENSE has passed high voltage test at the factory, and batch sampling tests are carried out on quarterly basis. The complete testing procedures help ensure the safety and reliability of isolators.

Closing remarks

The following sections of a datasheet basically include specific pin layout diagrams, property parameters, description of details, detailed measured results, application note, package size diagram, and certification guide, providing references for engineers in different stages of system design.

Since isolators are not master chips, there are not many do’s and don’ts in their service. For products like main processor, their datasheet may have hundreds of pages. As isolator is safety critical, engineers need to read all the relevant information carefully and fully.

In the analysis of the datasheet from NOVOSENSE, we have understood how important the key parameters of digital isolator are in product selection, and have got a basic knowledge of safety standards. We also have seen the obvious progresses of devices from NOVOSENSE and Chinese chip makers at large. This is attributable to NOVOSENSE’s ongoing R&D investment, and its product development approach of getting close to applications and market requirements.

In a nutshell, if you want to use a product or technology well, the first step is to understand it, and the best way to do so is to read its datasheet.